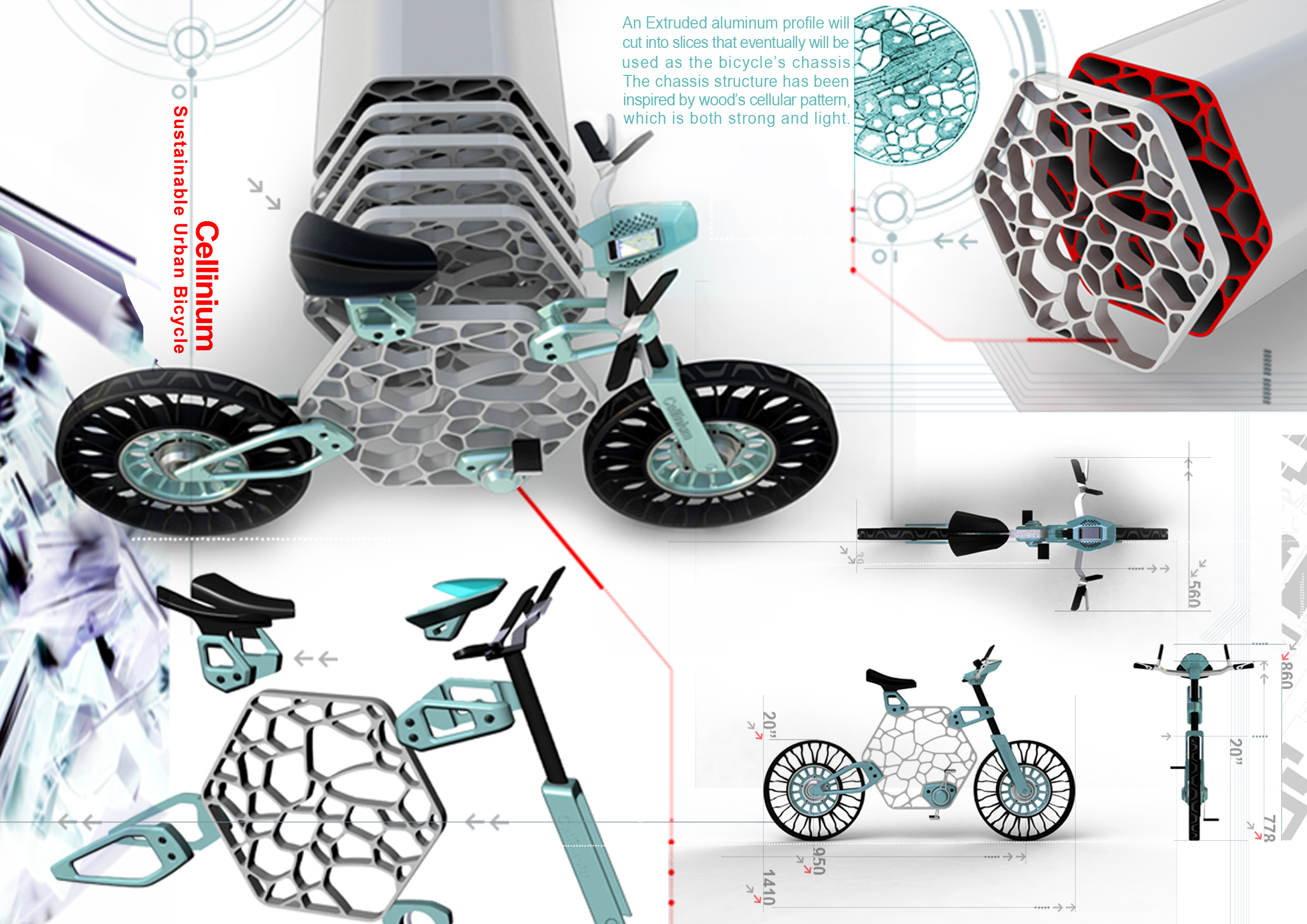

Cellinium’s frame will be manufactured using aluminum extrusion technique that requires minimum tooling. The external forces applying to hexagonal profile will be evenly distributed thanks to the clever cellular patterns inside. The reinforced aluminum profile will be cut in 70 cm thickness and the parts will be anodized afterwards to reach their maximum strength and durability. The eco-friendly manufacturing and assembly line skips the paint and coating process altogether.

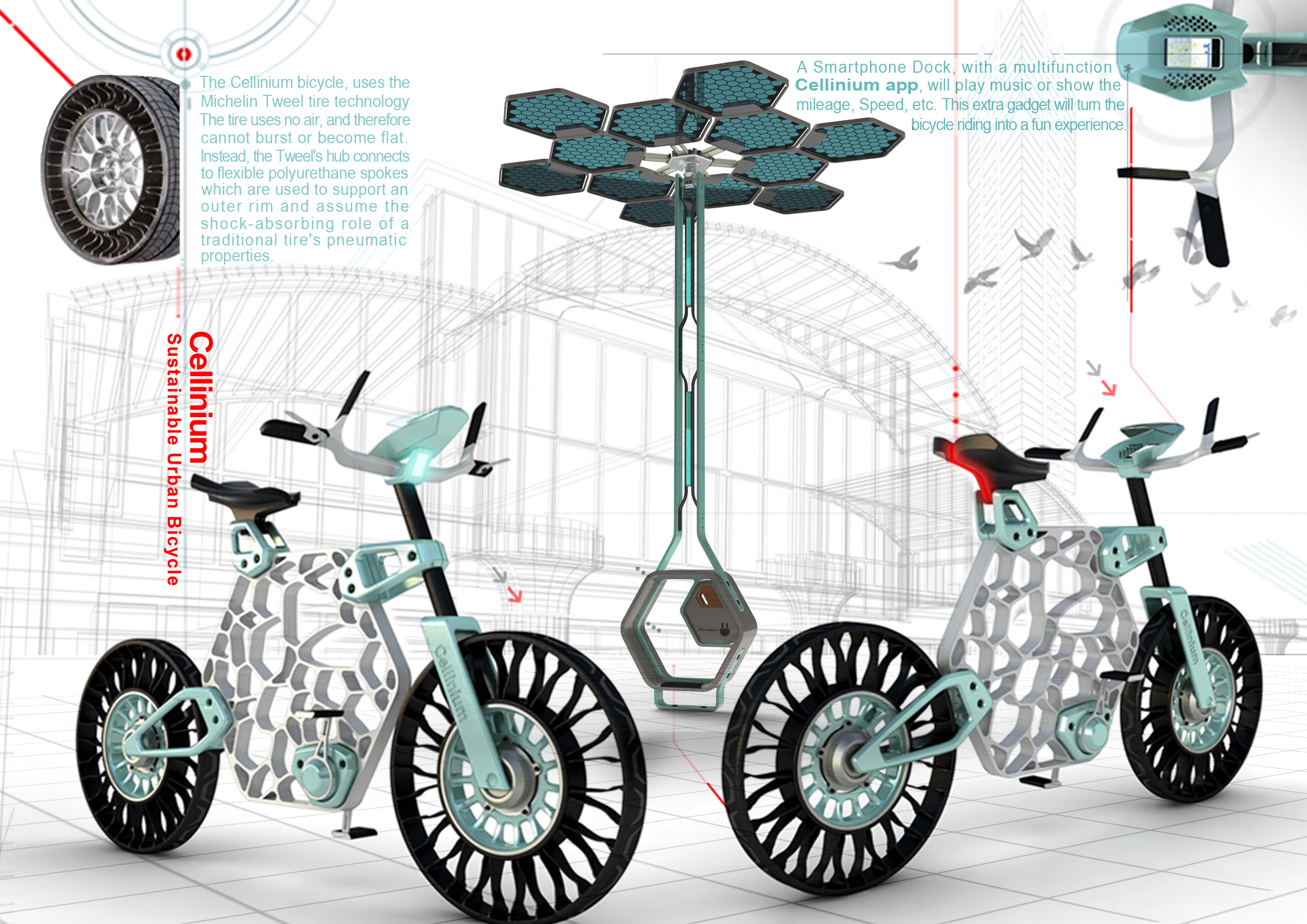

Electric motor in mounted in the wheel hub, and the tires use the Mischelin’s Tweel technology that will never run flat.

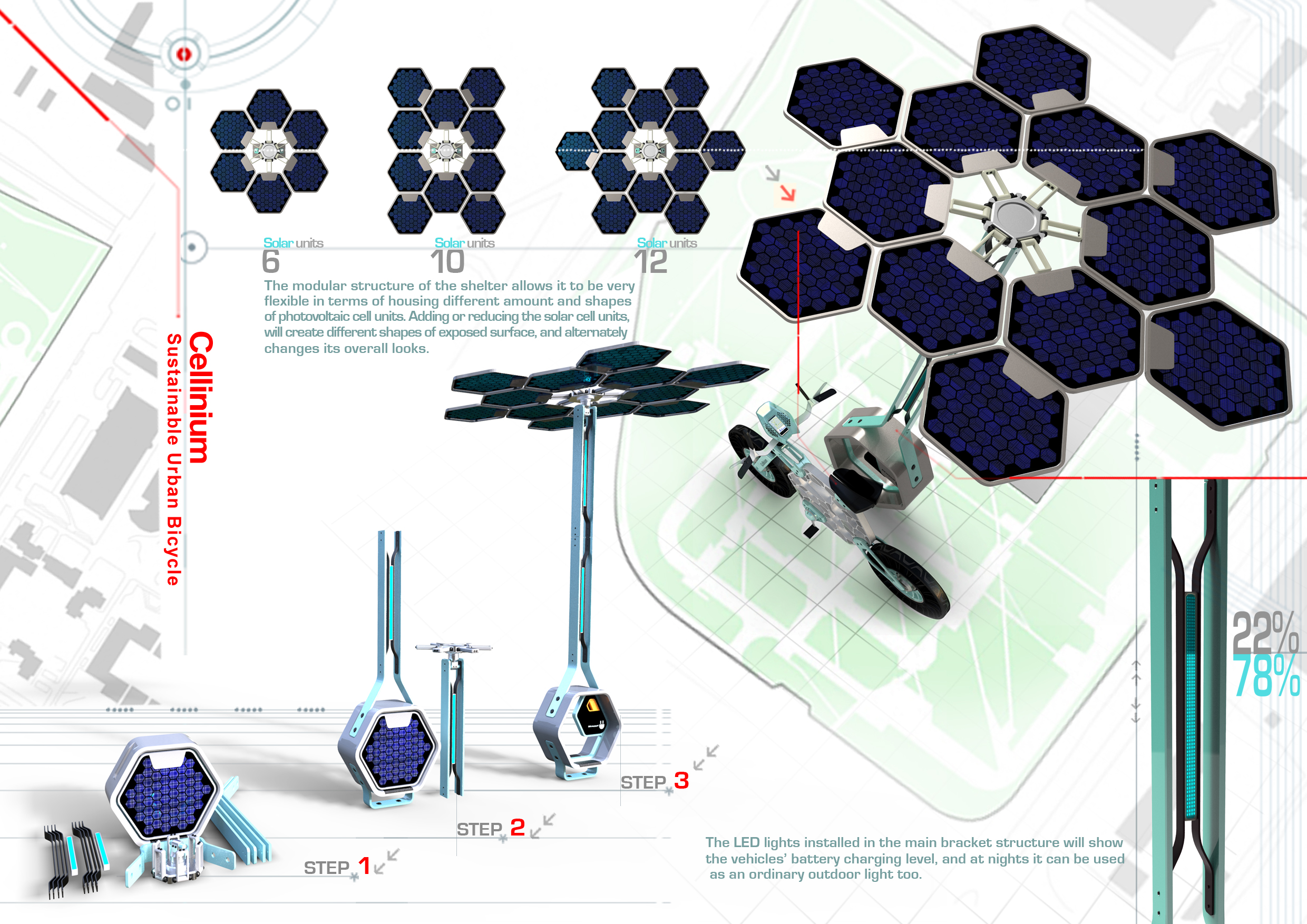

Solar panels power the urban charging stations, so the stations are off the grid. There is literally nothing much to brake, and the system has minimum environmental impact, which makes it the ultimate sustainable and durable urban transportation system.