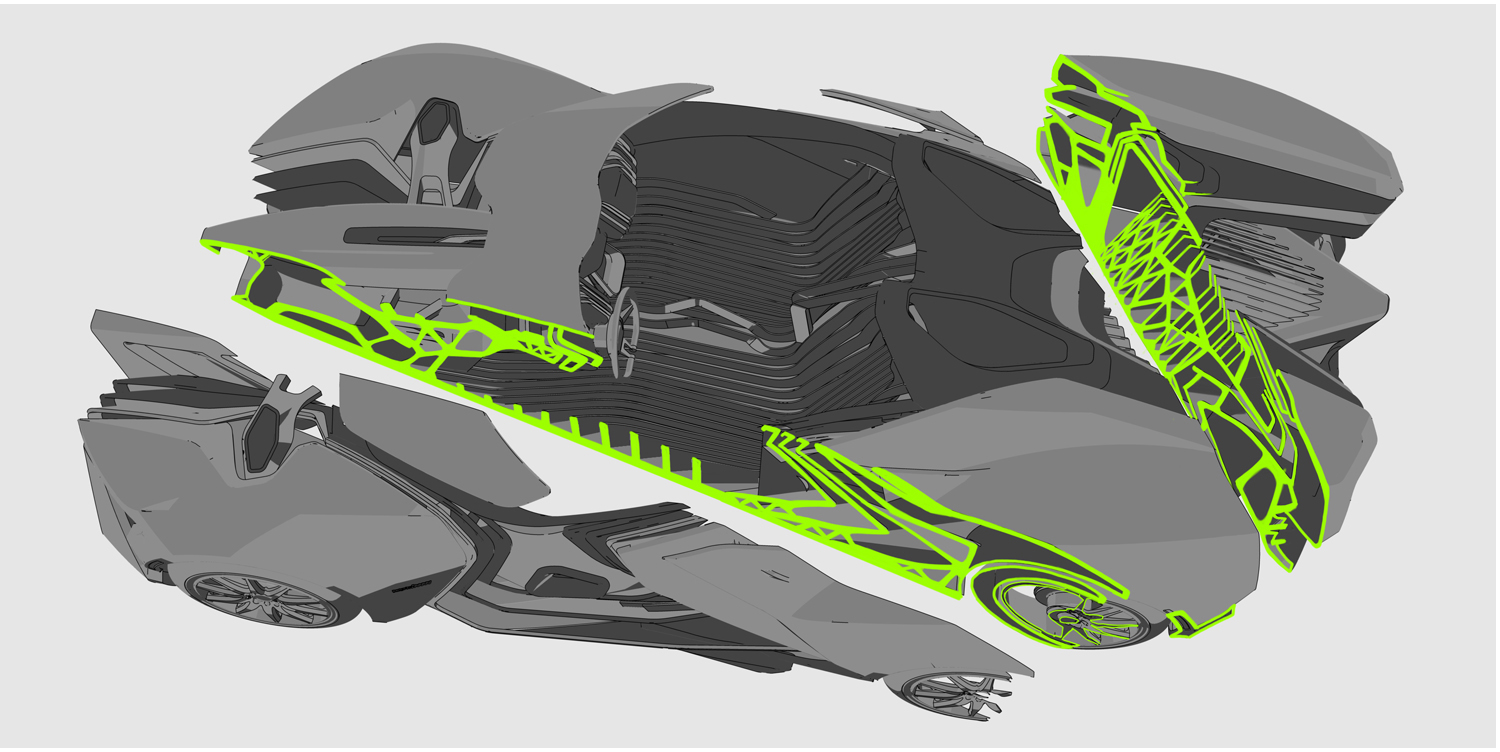

Aeroblade has been designed to take full advantage of large scale carbon 3D printing technology developed by Cincinnati University. The idea is to 3D print the chassis and most of the interior in one piece and then install the electric power-train and prefab fiberglass body panels to make the car in the most efficient way possible.

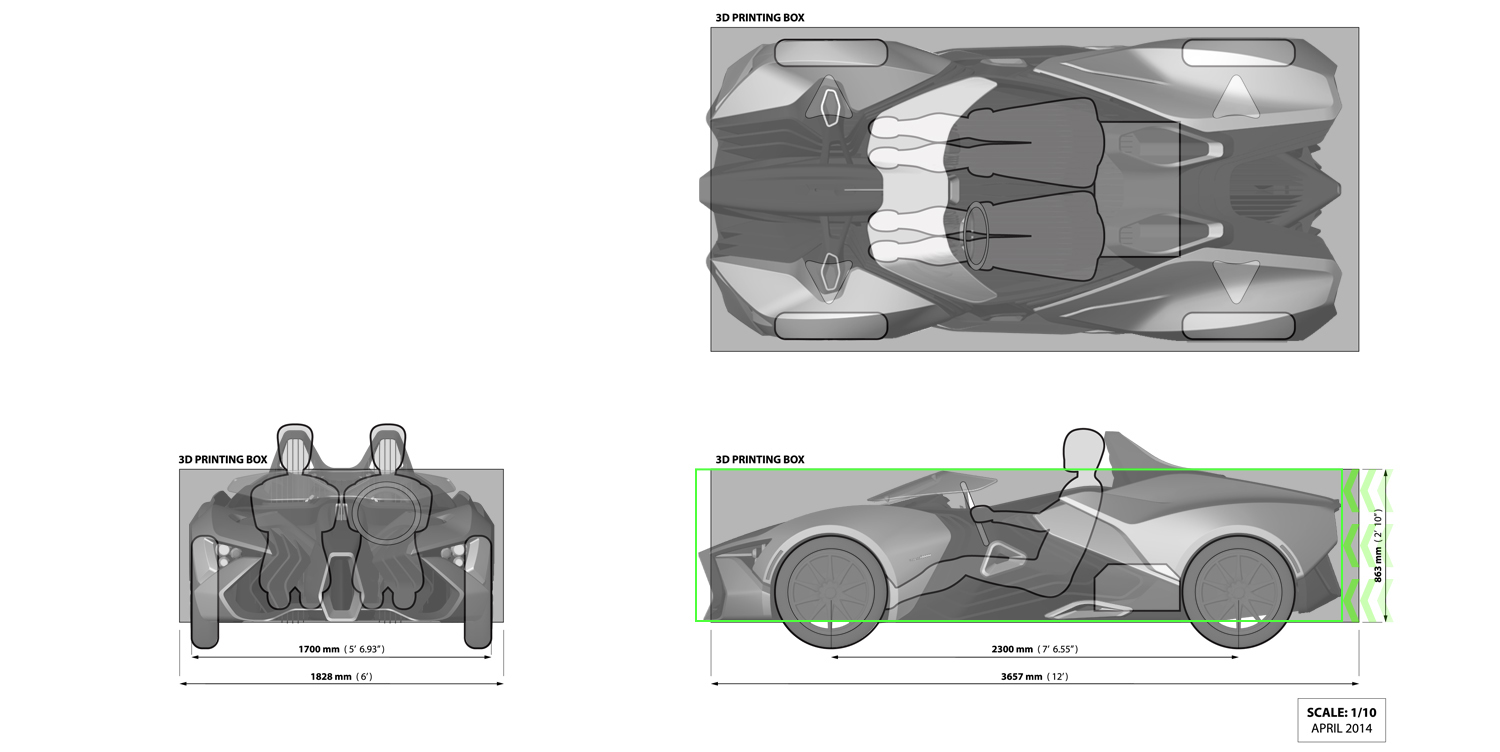

The car’s package has been designed in a very compact layout, by leveraging the benefits of a one piece 3D printed chassis.

3D printed blades in the chassis, channel the air through out the vehicle and provide proper ventilation for the batteries and down force on the wheels.